Floor renovation | Polished concrete | Terrazzo

Polished concrete

Is it worth paying extra for polished concrete when you can do a cheaper concrete floor?

Yes, because in practice Investment in polished concrete pays off very quickly - Most often within several months. This is due to the real savings in the daily use of the floor. After this time, the floor simply begins to monetize.

The most important benefits are lower cleaning costs, lower energy consumption (due to better light reflection), and less wear and tear on machinery and equipment, which operate on a smooth, dust-free surface. In the long run, this means fewer repairs, less downtime and significantly lower operating costs for the entire facility.

What is polished concrete?

Polished concrete is created by mechanically processing an existing concrete floor, both new and long-standing. This uses diamond tools and planetary grinders to grind and polish the surface, and during the process the concrete is further chemically hardened, which eliminates dust and increases abrasion resistance. Finally, a suitable impregnation can be applied, tailored to the conditions of use and the type of dirt.

How does polished concrete reduce a facility's energy costs?

Thanks to its high gloss and high reflectivity polished concrete effectively reflects light - as much as about 30% more than a standard concrete floor. In practice, this means that the facility is brighter with the same lighting.

This allows reduce the number of luminaires or lower their wattage, which directly translates into lower electricity bills. At the same time, it is easier to meet the required standards for lighting intensity, especially in halls, warehouses and industrial facilities.

What is the real life expectancy of polished concrete flooring and what are the warranty terms?

Polished concrete is distinguished by very high durability, therefore under the right conditions it is possible to give Warranty for up to 20 years For dust containment. This is far more than most standard flooring.

For the investor, this means Peace of mind for years of use, without the need for frequent repairs, resurfacing or costly renovations. The floor retains its technical and functional properties for a long time, even under intensive use.

Is it worth choosing polished concrete for an industrial hall?

Polished concrete floors are an ideal industrial solution because they are characterized by extreme abrasion resistance and heavy loads, which guarantees longevity without the need for frequent renovation. Thanks to dust-proof, smooth surface maintenance costs are minimal, and cleaning is simple and fast. Moreover, the high degree of reflection of natural and artificial light reduces energy consumption and improves working conditions in production halls and warehouses.

How does polished concrete affect forklift operating costs and facility speed?

Perfectly smooth, hardened and even surface significantly reduces vibrations and shocks While driving forklifts. With this tires, bearings and suspension components wear out more slowly, and the equipment itself runs quieter and more stable.

In practice, this translates into lower failure rate, lower maintenance costs and the possibility of smoother and faster logistics. A level floor also improves safety of operators and transported loads, which is of real importance in heavily used halls and warehouses.

Is polished concrete as slippery as an ice rink?

This is one of the most frequently repeated myths. Polished concrete is not inherently slippery and can easily meet the current anti-slip standards. This is confirmed by tests performed directly on finished floors.

In practice, polished concrete floors reach grades of R9, R10 and even R11, depending on the surface finish and the type of impregnant used. The key factors are the manufacturing technology, the degree of polishing, the surface texture and the properly selected impregnating product.

As a result, the floor can be precisely match the conditions of use From warehouses and production halls, to traffic routes, to facilities with increased safety requirements.

Renovation of industrial floors

How to prevent dusting of concrete floor?

Any concrete floor, even if it was cured with DST sprinkle, should be further cured with a silicate-based agent. The preparation penetrates the concrete and permanently thickens it, thanks to which it will not dust. The floor becomes stronger, more resistant to abrasion and easier to maintain.

Will the floor be slippery like an ice rink?

No. The gloss is an optical illusion. We test the coefficient of friction with a certified device. It is safe and in accordance with health and safety standards.

Do I have to close the plant for a week?

Absolutely not. The technology is dust-free (industrial vacuum cleaners) and odor-free. We can work in zones, at night or on weekends.

We have very deteriorated concrete with holes.

We make spot repairs, reprofile expansion joints and remove tire marks. We restore functionality even to old floors.

What is the minimum area of floor restoration that you implement?

We perform concrete floor restoration services on industrial and commercial sites. As a standard, we carry out orders in which the area of a single room is not less than 500 m².

However, we allow for situations in which the subject of the service is a large total area, and a small part of it is smaller rooms (e.g., facilities, communications, technical rooms).

Terrazzo floors

What types of terrazzo flooring are there?

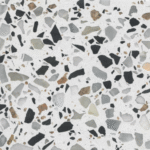

Terrazzo floors They are divided into two main types with cement and resin binders. There are also modified mixes in the cement version, such as those with additives to improve strength and flexibility. All types of terrazzo use decorative aggregates, such as marble, granite, quartz, glass or even shells of different granulations, which allows to create diverse visual effects.

sample of terrazzo exclusive

Can resin-based terrazzo be equated with standard resin flooring in terms of technology and workmanship?

Resin flooring is a completely different type of flooring and cannot be compared at all with the Resin terrazzo is a completely different technology, requiring specialized equipment (different machines), advanced laying, troweling, grinding, polishing and dedicated skills. Narrow specialization and experience are required. A company that lays standard resin is unable to make resin-based Terrazzo to the right quality standard. Likewise, a company that specializes in terrazzo is not in the business of making large areas of resin flooring.

Do resin-based terrazzo floors yellow faster?

Over time, any terrazzo changes shade, both resin and cement, so the belief that resin yellows more is a myth. Modern resins contain additives to increase UV resistance, but the color is also affected by surface micro-damage, the protective layer and the natural absorbency of the floor in the case of cement-based floors. The most important thing is professional workmanship and proper care then color changes are minimal, even and in most cases not a problem.